Traitement des eaux usées résidentielles, commerciales, communautaires, municipales et industrielles

Premier Tech Aqua develops and puts on the market innovative technologies, performing and cost-effective, for the decentralized wastewater treatment requiring a minimum of operation and maintenance. Its product line comprises the Ecoflo® Biofilter, a peat base treatment system for domestic wastewater. With its RotoFix MD ,its EcoflexMD and its BioSegMD treatment systems, the enterprise treats wastewater from commercial, communal, municipal and industrial projects. Another of its specialty is the treatment of residual water like leachate (landfill site). Its also offers a complete line of high performance peripheral products like: septic tank, effluent filter, pumping station, polyethylene accessories for septic tanks in concrete, flow dividers, etc. Premier Tech Aqua is one of the rare enterprises in the wastewater treatment decentralized industry, if not the only one, providing a professional service, before, during, and after the completion of an installation as well as for the entire useful life of the wastewater treatment system.

Description of the technology

Residential use

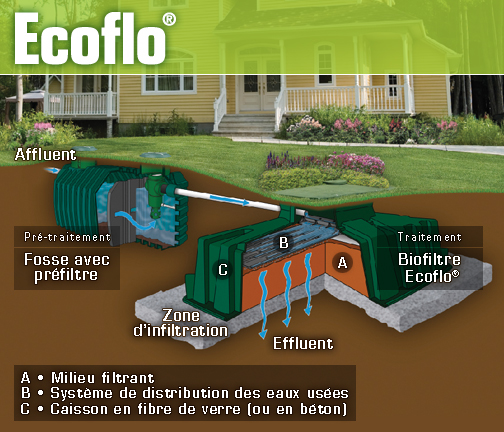

The Ecoflo® Biofilter is an entirely autonomous water treatment system, consisting of a relatively small fiberglass shell and a filter using specially treated peat-moss. Its design allows it to treat up to 1,000 litres of water daily. The process is simple; wastewater from the septic tank is piped into the shell where it is uniformly distributed over the entire surface of the filter by means of a gravity system. Wastewater is then cleansed by percolating through the peat-moss filter bed and is finally discharged either by infiltration into the soil or by dilution in a steadily flowing stream (in conformity with applicable legislation).

Commercial, institutional and community uses

The results obtained in residential applications with the Ecoflo® biofiltration system have led to its adaptation for use in certain collective and commercial applications, such as restaurants, hotels, small clusters of homes, etc. To meet these demands, a series of Ecoflo® Biofilter units would generally be installed. The addition of a pump and a flow separator at the outlet of the septic tank may also be required to ensure even distribution of the wastewater to the various biofiltration units.

Performance

The physico-chemical and micro-biological characteristics of the peat-moss filter bed produce 90 % retention of suspended solids (SS), 95 % degradation of biodegradable organic matter and 99 % elimination of pathogenic organisms (coliforms).

Advantages

The Ecoflo® Biofilter offers the following clear advantages, in comparison with conventional wastewater treatment systems (sewage field, sand filter, etc.).

- Compact system

- Flexible installation

- Permanent installation

- No constraints on landscaping

- No electrical components

- Better and continuous purification results

- Protection of groundwater

- Guarantee and service included with purchase

- Complete septic installation eligible for financing

Maintenance and guarantee

Maintenance

An annual follow up which consists of an inspection and a maintenance of the system is performed on the Ecoflo® Biofilter. The lifespan of the filtering media is 10 years (under normal utilization conditions) and its replacement is carried out with the same type of truck to empty septic tanks. This particularity allows easy access to the lid of Ecoflo® and therefore the owner avoids excavating works and keeps the landscaping intact. The filtering media can also be subject to revalorization.

Warranty

A 20 year warranty is offered on our concrete or fiberglass shells and also on the components of the Biofilter. The filtering media has a 10 year warranty that is transferable at all times.

Residential applications

The Ecoflo® Biofilter is an autonomous septic system which consists of a fiberglass or concrete shell and a peat based filter. It can treat up to 1000 litres of wastewater per day. Its principle is simple; wastewater from the septic tank is directed to the Ecoflo® Biofilter where it is evenly distributed over the entire surface of the natural filtering media using gravity distribution system. The water is then filtrated as it percolates through the filtering media and is finally discharged to the absorption bed underneath the Ecoflo® or into a watercourse with continuous flow (according to the regulation in force).

Installation requirements

n light of the different rules that apply from one province or state to another in North America, we can only present general information on Ecoflo® Biofilter installation. It is performed by an authorized installer, trained by Premier Tech Aqua.

Dimension of the Ecoflo® shell are 4.2 m (13′-10″) long by 2.4 m (7′-11″) wide by 1.3 m (4′-4″) high. System installation requires the presence of a minimum thickness of permeable soil in a non-flood zone. Effluent discharge can be accomplished in one of two ways: either by infiltration in surrounding soil or by adequate dilution in a steadily flowing watercourse.

Ecoflo® Biofilter technology is tested under the Canadian Government’s ETV program: “Performance claims criteria through the Environmental Technologies Verification Program“.

Costs

Premier Tech Aqua, you can obtain the coordinates of an authorised installer who will evaluate the costs for a complete septic installation. A septic installation using the Ecoflo® Biofilter is eligible for financing.

Treatment of leachates from sanitary landfills

Modern landfill sites perform better as a result of being more water-tight and by virtue of operating programs which ensure tighter control of emissions (leachates and biogas).

In order to satisfy new criteria put in place in various countries, two issues need to be dealt with in regards to the treatment of leachates from sanitary landfill sites. They are:

- Need for improved performance by leachate treatment systems to meet more stringent discharge parameters;

- Need for economical solutions for closing sanitary landfill sites.

Premier Tech Aqua offers a new approach to treating leachates by adding in a polishing unit to the aerobic and anaerobic treatment systems in place on municipal landfill sites. This concept uses proven processes in a combination which provides excellent purification results and effluent quality exceeding applicable norms, at a competitive price.

Description du procédé de polissage

The polishing process is based on a percolating filter bed consisting of an organic medium working in aerobic conditions. Leachate input is aided by a low-pressure distribution system located above the bed coupled with a passive aeration system

As illustrated, the polishing unit is integrated downstream of the aerobic and anaerobic ponds or tanks, or after an equivalent treatment, depending on the volume of leachate to be treated. Here are the principal characteristics of the process:

- Meets legislated discharge norms (BOD, SS, COD, NH4, metals, etc.)

- Stable performance despite variable leachate characteristics

- Long term effectiveness of cleansing performance

- Simple process allowing nitrification

- Option of integration in existing systems

- Economical solution for closing sites or for new cells

- Simple operation and maintenance

- Low energy consumption

Installation flexibility

The polishing unit is a modular process which can be installed in different types of confinement cell and in various possible configurations. The unit can be easily extended to match the expansion over time of a landfill site.

Polishing system performance

Tests of the polishing unit have given the following performance parameters:

It is also possible to obtain higher performance by combining two polishing phases, each one using a specific filter medium, thereby minimising the total surface area required. This combination allows results to be maximised for the majority of parameters, thus obtaining a treated effluent which meets the most stringent norms.

Premier Tech ltée

1, avenue Premier, C.P. 3500

Rivière-du-Loup, Québec, G5R 4C9

Phone : 1-800-632-6356

Phone : 418-867-8883

Fax : (418) 862-6642

Email : pta@premiertech.com